Micro Summary Card

The Human Touch in a Digital World

Hand-carving stone remains the gold standard for high-end, one-of-a-kind masterpieces. Unlike a machine, a master carver can “read” the stone, adjusting the angle of the chisel to account for natural veins, hidden fissures, or density variations in marble furniture.

-

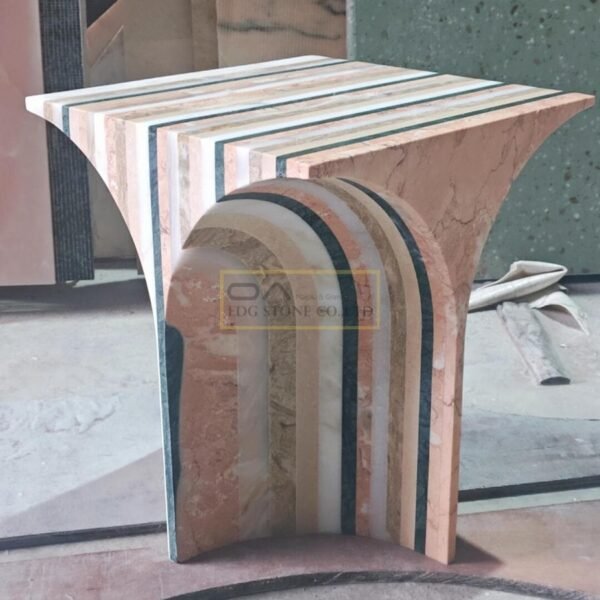

Tactile Depth: Hand-carved reliefs possess a “vibration” and organic depth that CNC machines often struggle to replicate. The subtle irregularities in a hand-finished travertine furniture table base create a sense of history and human connection.

-

Artistic Modification: During the carving process, a craftsman can make real-time creative decisions, enhancing a floral motif or a geometric curve based on how the light hits the material.

-

Market Positioning: Items marketed as “100% Handcrafted” often command a 30-70% premium in the luxury retail sector, particularly for handcrafted vs machine-made comparisons in collector-grade pieces.

Marble Furniture

Part 2: CNC Stone Carving — The Pinnacle of Precision

Scaling Luxury with Technology

CNC carving stone (Computer Numerical Control) has revolutionized the capacity of any stone furniture manufacturer. By using 5-axis milling machines, factories can translate complex CAD files into physical reality with a tolerance of less than 0.001 inches.

-

Consistency for Wholesale: For hospitality projects requiring 200 identical limestone furniture side tables, CNC stone carving is the only viable solution. It ensures that the first unit is identical to the last.

-

Complex Geometries: Modern CNC stone technology can execute “impossible” shapes—internal voids, interlocking stone joints, and ultra-thin lattices—that would be too risky or fragile to attempt by hand.

-

Efficiency and Cost: Data from 2025 indicates that CNC-assisted production reduces labor costs by approximately 40% for structural shaping, allowing Sunlife Stone to offer competitive pricing for wholesale stone furniture.

The Decision Matrix: Hand-carved vs. CNC Machined

| Feature | Hand-Carved | CNC Machined |

| Uniqueness | High (No two pieces are identical) | Moderate (Perfectly repeatable) |

| Production Speed | Slow (Weeks to Months) | Fast (Hours to Days) |

| Intricacy | High (Artistic/Organic) | High (Geometric/Mathematical) |

| Labor Cost | Very High | Lower (Automated) |

| Sustainable Waste | Moderate (Skill-dependent) | Low (Software Optimized) |

Material Specifics: Marble, Limestone, and Travertine

The material choice often dictates the machine’s role.

-

Marble Furniture: As a denser material, marble responds exceptionally well to CNC milling, but requires high-grit hand polishing to achieve its signature luster.

-

Travertine Furniture: The porous nature of travertine means CNC paths must be carefully programmed to avoid “chipping” the edges of the natural voids.

-

Limestone Furniture: Often used for large-scale architectural carvings, limestone is the perfect candidate for a “Hybrid” approach—CNC for the bulk removal and hand-tooling for the surface texture.

2026 Industry Trends & Regulatory Landscape

Sustainability and the “Green” Stone Factory

The 2026 regulatory environment, specifically the EU’s Ecodesign for Sustainable Products Regulation (ESPR) and California’s SB 219, has forced manufacturers to report the carbon footprint of their production.

-

Water Recycling: Modern CNC machines at Sunlife Stone utilize closed-loop water filtration systems, reducing water waste by 95% compared to traditional open-flow hand workshops.

-

Waste Management: AI-optimized CNC nesting software reduces stone scrap by 15-20%, a critical factor as the industry moves toward circular economy models.

-

Market Growth: The luxury stone furniture market is projected to grow at a CAGR of 5.73% through 2032, with “Eco-Certified Stone Furniture” being the fastest-growing sub-segment.

CNC Stone Carving

People Also Ask

- Can a CNC machine carve stone?Yes, specialized stone CNC machines (typically 3-axis or 5-axis) use diamond-tipped tools and high-pressure water cooling to mill, carve, and engrave natural stones like marble, granite, and limestone with extreme precision.

- How to tell if furniture is hand-carved?Look for slight asymmetries and tool marks. Hand-carved stone often has deeper, more varied undercuts and a surface texture that isn’t perfectly uniform. CNC-made pieces often show very faint, consistent “path lines” before they are polished.

- What is CNC in furniture?In the furniture industry, CNC refers to Computer Numerical Control machines that automate the cutting, shaping, and carving of materials (stone, wood, metal) based on a digital 3D model, ensuring high speed and repeatability.

- What qualifies something as handmade?While definitions vary, “handmade” generally requires that the significant creative and technical work—especially the final shaping and finishing—is performed by a craftsman using hand-held tools, even if power tools are used for initial roughing.

- Is CNC outdated?On the contrary, CNC technology is currently at its peak. In 2026, the integration of AI with CNC machines allows for predictive maintenance and even more complex, generative designs that were previously unachievable.

Hand-carved Stone

FAQ: High-Intent Purchasing Questions

Q1: Is CNC stone furniture cheaper than hand-carved furniture?

Generally, yes. CNC stone carving reduces the man-hours required for the “bulk” of the work. However, a hybrid piece that is CNC-cut but hand-finished by an artist may still carry a premium price due to the skilled labor involved in the final details.

Q2: Can I get a custom design from a stone furniture factory?

Absolutely. Most modern stone furniture manufacturers like Sunlife Stone accept CAD or Rhino files. We can transform a digital sketch into a custom marble furniture piece in a fraction of the time it would take a traditional sculptor.

Q3: Which is more durable, hand-carved or machine-made?

The durability is determined by the stone type (e.g., Marble vs. Travertine) rather than the carving method. However, CNC machines provide better structural consistency, ensuring that load-bearing joints in tables are perfectly square and stable.

Q4: Does Sunlife Stone offer wholesale pricing for commercial projects?

Yes, as a direct stone furniture factory, we provide wholesale stone furniture rates for architects, developers, and retailers. Our CNC capacity allows us to handle high-volume orders for hotels and luxury residential developments.

Q5: Are CNC machines eco-friendly?

When equipped with modern water-recycling and dust-collection systems, CNC machines are often more eco-friendly than manual carving. They optimize material usage to minimize stone waste and protect workers from inhaling stone dust (silica).

Defining the Future of Stone Craftsmanship

The intersection of stone furniture design and manufacturing technology has reached a pivotal moment in 2026. As the global natural stone market scales toward $54.9 billion by 2032, the dialogue between the “soul” of handcrafted stone and the “logic” of machine-made precision is no longer a binary choice. It is a strategic synergy. For architects, interior designers, and luxury furniture wholesalers, understanding the nuances of CNC carving stone versus hand carving stone is essential for optimizing project timelines, budgets, and aesthetic outcomes.

Reference & Professional Citations

-

The Business Research Company (2025): “Natural Stone Market Size, Growth Outlook, and Global Forecast 2025-2029.”

-

Fortune Business Insights: “Luxury Furniture Market Size & Forecast [2032] – Analysis by Material & End-User.”

-

European Commission (2025): “The Clean Industrial Deal: Implementation of the Ecodesign for Sustainable Products Regulation (ESPR).”

-

Technavio Research: “Global Luxury Furniture Market Growth Analysis 2024-2028.”

-

Straits Research: “Global Luxury Furniture Market: Regional Insights and Tech-Driven Trends.”

-

American Bar Association (2025): “Environmental Sovereignty: How EU Sustainability Regulations Impact Global Manufacturing.”

-

Stone World Magazine: “Advancements in 5-Axis CNC Milling for the Dimensional Stone Industry.”

-

Journal of Cleaner Production: “Life Cycle Assessment (LCA) of Natural Stone vs. Synthetic Materials in Interior Design.”

Industry Insight & Strategic Selection

How to Choose Between Hand-Carved and CNC Stone Furniture

When selecting stone furniture for a luxury project, the decision-making process should follow a three-tier logic: Volume, Complexity, and Emotional Value.

- Choose CNC Machining for: Modular designs, geometric tables, large-scale commercial furniture (wholesale), and projects with strict 4–6 week lead times. It is the most cost-effective way to achieve modern, minimalist aesthetics in marble or limestone.

- Choose Hand-Carving for: Ornamental centerpieces, classical statuary, and bespoke residential pieces where the “artist’s signature” is a selling point. Hand-carving is essential for achieving deep undercuts that a 5-axis drill bit cannot reach.

- The 2026 Hybrid Standard: The most successful luxury brands now use CNC for the 80% structural work and Hand-finishing for the 20% surface detail. This “Tech-Artisan” approach maximizes ROI while maintaining the “Handcrafted” soul.

Pro Tip: Always verify if your stone furniture manufacturer complies with the latest ESPR (EU) or Scope 3 (US) emission standards to ensure your project meets future sustainability audits.