Quick Summary:

Quick Summary: Travertine—long admired for its warm tones and porous texture—has re-emerged as a leading material in 2025, driven by biophilic design, new fabrication/finishing techniques, and stronger sustainability and safety standards. This article explains why designers and buyers (including manufacturers and factory/wholesale channels like Sunlife Stone) are choosing travertine for furniture, floors, and feature surfaces; compares travertine vs. marble; outlines sourcing & price drivers; details installation and care.

Introduction: Travertine’s renewed moment in contemporary design

Travertine is having a moment. After decades of oscillating popularity, this warm, textured, and porous limestone is now favored for tactile interiors, sculptural furniture, and modern rustic schemes. Designers and manufacturers are embracing the stone’s character — its pitted surfaces, subtle veining, and range of warm tones — as an antidote to over-polished minimalism. In 2025, travertine appears in high-end dining tables, textured bathroom vanities, large-format wall cladding, and even outdoor terraces where its natural patina reads as timeless and intentionally aged. Industry thought leaders and major manufacturers list travertine among the top natural-stone trends for 2025, calling it a material that reconciles modern lines with tactile, human-scale surfaces.

This article is written for designers, procurement teams, manufacturers (factory/wholesale channels such as Sunlife Stone), and homeowners who want a practical, evidence-informed guide to specifying travertine in 2025: when to choose it, how to budget for it, what finishing and care mean in practice, and which regulatory and safety considerations to bake into your RFQs and contracts.

travertine texture

Design drivers: Why porous textures resonate in 2025?

Biophilia, tactility, and the warmth economy

Design in the mid-2020s is pivoting toward the tactile and the authentic. Travertine’s porous surface reads as organic and aged, instantly adding warmth and a handcrafted feel to interiors. As biophilic design and “refined layering” sensibilities grow, materials that engage touch and display natural variation—rather than engineered uniformity—are preferred for living spaces and hospitality projects.

Wabi-sabi and the value of imperfection

Part of travertine’s appeal is cultural: a growing appreciation for imperfection, patina, and materials that evolve with use. Designers are deliberately exposing filled and unfilled pores, alternating honed and brushed textures, and pairing travertine with warm woods and matte metals to create layered, lived-in interiors.

Application breadth: from furniture to façades

Travertine is no longer only a flooring or cladding stone. Improved finishing and reinforcement techniques have enabled travertine dining tables, benches, and sculptural consoles. On walls and in bathrooms, large-format travertine slabs create tactile backdrops that reward both sight and touch. Manufacturers now offer purpose-made travertine elements—pre-cut table tops, precision-joined slabs, and factory-ready furniture components—which makes travertine more accessible to contemporary projects.

Sunlife Stone

Travertine vs Marble: visual character and performance

Visual differences: pores, color, and patina

Travertine is a form of limestone deposited by mineral springs; it features pitted cavities and a softer, more matte aesthetic than many marbles. Marble typically polishes to a high gloss and shows more pronounced veining, while travertine’s charm is in subtle veining, warm beige/ivory/cream tones, and porous texture. Where marble reads as luxurious and formal, travertine reads as warm, subtle, and tactile.

Performance: porosity, hardness, and durability

Technically, travertine tends to be softer and more porous than many dense marbles. On Mohs scale approximations, travertine often registers around 2–3, while many marbles are closer to 3–4, which affects scratch and abrasion resistance. Proper filling, sealing, and finishing mitigate much of travertine’s vulnerability in moderate-use interiors, but in very high-traffic commercial floors or heavy-abuse countertops, denser marbles or quartzites may be preferred.

Use-case matrix: where travertine outperforms marble

-

Best for: textured feature walls, vanities, dining tables, low-traffic floors, terraces with slip-resistant finishes, and hospitality projects seeking warmth.

-

Less ideal for: heavily used kitchen countertops near acidic exposures or industrial floors unless sealed and engineered appropriately.

travertine stone price

Sourcing & pricing: how the market and factories influence choice

Travertine market signals in 2025

Natural stone markets are expanding overall: industry analyses estimate a robust global natural stone market in 2025 with steady growth into the coming decade, reflecting rising construction and renovation demand. Within that broader market, travertine is projecting renewed demand driven by design trends and product innovation, with market reports projecting steady compound annual growth for travertine segments over the next decade. These macro signals make travertine an attractive product line for stone manufacturers and wholesale suppliers.

Price drivers: grade, finish, origin, and processing

Travertine pricing varies by origin (Turkey, Iran, Mexico, Italy, etc.), vein clarity, slab size, and whether the stone is filled or left raw. Premium “calibrated” travertines with consistent thickness and large-format slabs command higher prices. Additional costs include pore-filling, edge profiling, lamination for furniture tops, and higher-grade sealers.

Manufacturer/factory vs wholesale procurement

Buying factory-direct (manufacturer/factory) gives specifiers control over slab selection, bookmatching, and custom finishes—important for furniture makers and boutique hospitality projects. Wholesalers and distributors may offer faster delivery for standard tiles but less slab-level selection. For high-visibility pieces (dining tables, bookmatched feature walls), insist on slab photos, slab IDs, and production samples in your RFQ.

Lead-times & logistics

Custom travertine orders—especially bookmatched slabs or finished furniture tops—require longer lead times. Factor in quarry lead, finishing, and international shipping when planning projects; supply chains and port congestion remain variables to manage.

travertine vs marble

Fabrication & finishes: filling, sealing, and furniture-ready travertine

Filled vs unfilled finishes: aesthetic and practical trade-offs

Porosity is travertine’s signature. In “filled” finishes, installers fill the natural cavities with color-matched resin or cementitious fills to create smoother surfaces suitable for tabletops and floors. “Unfilled” (or partially filled) finishes preserve the natural cavity texture to emphasize tactility and authenticity. Choose fills sparingly for furniture that must be easily cleanable, and choose unfilled for feature walls or shelving where texture is desired.

Edge treatments, lamination, and structural reinforcement

Large travertine furniture tops often require laminated layers or a plywood/epoxy substrate for stability and to prevent warping. Edges can be profiled, eased, or left square, depending on style. For dining tables, reinforcement—steel or composite subframes—prevents cracking and ensures longevity.

New sealing technologies and low-VOC products

Sealers preserve appearance and reduce staining, but the industry has shifted toward low-VOC impregnators and finishes to meet indoor-air-quality standards. Specify low-VOC sealers when shipping to or installing in regulated jurisdictions and when clients require green-building certifications.

travertine dining table

Installation, maintenance, and long-term care

Tile & slab installation best practices

Travertine tiles need stable substrates and appropriate adhesives rated for natural stone. Because of porosity and variation in thickness, use proper bedding, leveling, and grout selection. For furniture tops, ensure correct substrate lamination and edge sealing before delivery.

Grout & joint choices

Select grout colors and joint widths that complement travertine’s natural tones. For porous, unfilled travertine walls, consider micro-joints or groutless systems when panels are large and tolerances are tight.

Maintenance: reseal schedules and stain response

Routine care: pH-neutral cleaners and soft mops/cloths. Resealing schedules depend on use—generally every 12–36 months for indoor surfaces; heavier-use or kitchen-adjacent pieces require more frequent checks. Stain remediation sometimes requires professional poultices or stone restoration.

travertine maintenance

Market data & regulation: what specifiers must know

Market context and growth

Analysts estimate steady growth for the global natural stone market in 2025 and beyond; demand for textured natural stones such as travertine is rising in design-forward segments. This macro trend supports investments by manufacturers and encourages wholesalers to broaden travertine SKUs.

VOC & adhesive compliance

Many regions regulate VOCs in adhesives and sealers. For example, Rule 1168 and related CARB guidance set VOC limits for architectural adhesives and sealants that affect what products fabricators and installers can use in sensitive markets. Clients and specifiers increasingly insist on “1168-compliant” or equivalent low-VOC adhesives and sealers to ensure indoor air quality and project compliance.

Worker safety and silica controls

Stone fabrication generates respirable crystalline silica. Regulatory and safety bodies have tightened controls and enforcement on silica exposure—OSHA standards and construction-safety rules require engineering controls, training, and protective equipment. Buyers should require fabricators to demonstrate silica-safety programs and compliance as part of vendor selection.

Sustainability & traceability

Natural stone suppliers and manufacturers are adopting sustainability standards and third-party verification (for example, Natural Stone Institute’s sustainability program) to support client ESG requirements. Specifiers now often request quarry traceability, EPDs, or sustainability certificates as part of procurement.

manufacturer wholesale

Design inspiration: practical ways to use travertine in 2025 projects

Travertine dining table

A single, thick, bookmatched travertine slab with a minimal metal base creates a sculptural dining table. For usability, choose filled or semi-filled surfaces with an impregnating sealer and an internal plywood backing or steel subframe.

Feature walls and niches

Large-format slabs with selected filled pockets act as tactile backdrops for living rooms or hotel lobbies. Alternate honed panels with raw-textured inserts for contrast.

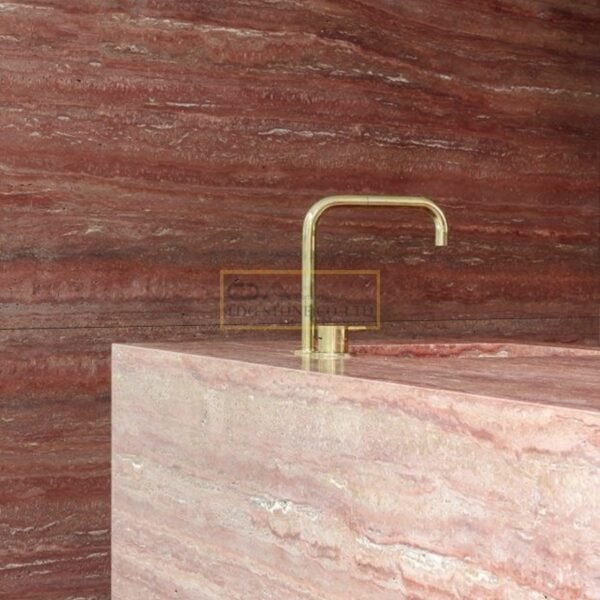

Bathroom vanities and basins

Honed travertine vanities provide a warm alternative to marble. For basin areas, sealed and filled tops paired with undermount basins balance aesthetics and cleanability.

Outdoor terraces and pool decks

Travertine with textured, anti-slip finishes works well outdoors; check frost resistance and finish type for local climates.

Pairings that work

Travertine pairs beautifully with warm wood tones, matte black or aged brass metals, and soft textiles. Use painted plaster walls and warm textiles to amplify the stone’s comfort-forward aesthetic.

low-VOC sealers

Pros & cons: Is travertine right for your project?

Advantages

-

Warm, timeless aesthetic that supports biophilic design.

-

Variety of finishes—filled, honed, brushed—enables broad applications.

-

Often less expensive than premium marbles while offering a distinct look.

-

Strong market demand in 2025 supports supplier and fabrication investment.

Drawbacks

-

Higher porosity necessitates careful sealing and maintenance.

-

Softer than many marbles and quartzites—less ideal for heavy-abuse surfaces.

-

Some clients misinterpret porosity as “fragility” — education is often required.

Decision checklist

-

Is texture and tactility a core design driver?

-

Will the surface be exposed to acids, heavy staining agents, or high traffic?

-

Do you need bookmatched slabs or custom furniture pieces?

-

Is factory-level reinforcement or lamination acceptable in your budget?

The rise of Travertine in 2025

FAQ — Google-hot questions

-

What makes travertine different from marble?

Travertine is a form of limestone deposited by mineral springs and is characterized by its porous texture and warm, earthy tones. Marble is typically denser and polishes to a higher gloss with more pronounced veining. In practice, travertine emphasizes texture and patina while marble emphasizes polish and veining. -

Are travertine floors outdated in 2025?

No—travertine is experiencing a resurgence in 2025. Designers favor its porous textures and warm palette for biophilic and tactile interiors. With modern finishes and sealing techniques, travertine floors are both fashionable and practical when specified correctly. -

How much does travertine cost compared to marble?

Prices vary widely by origin, grade, and finish. Generally, common travertine is often more economical than premium marbles (e.g., Calacatta), but cost parity occurs for rare or premium travertine slabs. Added fabrication (filling, lamination, custom furniture work) increases final costs. -

Is travertine suitable for furniture like dining tables?

Yes—travertine can be engineered into durable dining tables when slabs are filled where needed, bonded to stable substrates (plywood/epoxy), and reinforced with metal or composite frames. Proper finishing and sealing are essential for long-term performance. -

How should I maintain and seal porous travertine surfaces?

Use pH-neutral stone cleaners for daily care, and schedule resealing every 12–36 months, depending on use. Promptly address spills to prevent staining and follow manufacturer recommendations for impregnating sealers to preserve indoor air quality (choose low-VOC products where required).

Semantic Closure: How / Why / What / Options / Considerations

How: Specify travertine by slab ID, finish (filled vs. unfilled), thickness, and any reinforcement or lamination required for furniture. Require low-VOC sealers and documented silica-safety practices from the factory. Approve digital layouts and test samples before final fabrication.

Why: Travertine offers sensory warmth and textured surfaces that align with 2025 design trends—biophilia, refined layering, and the cultural embrace of patina and imperfection. It is a fast-growing niche in the natural stone market because it blends craft and contemporary design.

What: What to include in purchase orders: slab photos and IDs, bookmatching direction (if needed), fill level, edge profile, substrate lamination plans for furniture, sealer and adhesive product codes (low-VOC), and delivery/lead-time milestones.

Options: Choose unfilled travertine for authentic texture, filled travertine for tabletops and floors, or engineered quartzite alternatives where durability trumps porous aesthetics. Combine finishes (honed + brushed) to create layered tactile experiences.

Considerations: Factor lifecycle maintenance, reseal frequency, stain risk, and the need for factory silica-safety documentation into specifications. Prioritize suppliers who provide sustainability documentation (e.g., Natural Stone Institute programs) and confirm low-VOC product compliance in regulated markets.

References (author/title/source — no links)

-

U.S. Occupational Safety and Health Administration (OSHA) — “Respirable Crystalline Silica” — OSHA Guidance and Standards.

-

California Air Resources Board (CARB) — “Rule 1168: Adhesive and Sealant Applications” — CARB Regulatory Documents.

-

Mordor Intelligence — “Natural Stone Market: Industry Report (2025)” — Market Research Report.

-

Market Research Future — “Travertine Market Size, Forecast & Industry Analysis” — Market Research Report.

-

Porcelanosa — “Travertine: Interior Design Trendbook” — Industry Trend Publication.

-

MarmoElite — “Travertine: A Key Trend for 2025” — Industry Article.

-

Grand View Research — “U.S. Natural Stone Market Report” — Market Research Publication.

-

Industry Fabricator Technical Bulletin — “Best Practices for Mitering and Seaming Large Stone Panels” — Trade Publication.